Introduction to Structural Steel Fabrication

Structural steel fabrication is a pivotal process in the construction industry, combining engineering expertise with advanced technology to produce the steel components that support buildings, bridges, and other infrastructure. This process involves several stages including cutting, bending, and assembling steel to form the structures that are foundational to modern architecture. Understanding the nuances of structural steel fabrication is essential for contractors, architects, and engineers alike, as it significantly influences project timelines, budgets, and ultimately, the integrity of constructions.

What is Structural Steel Fabrication?

Structural steel fabrication is the process of constructing steel structures by cutting, shaping, and assembling steel components. It encompasses a wide range of activities including the use of automated machines and manual labor to produce the necessary steel parts. Fabricators start with raw steel, which is processed into various shapes, such as beams, columns, and trusses, tailored to meet specific design requirements.

Importance in Construction Industry

The role of structural steel fabrication in construction cannot be overstated. Steel is recognized for its strength, flexibility, and durability, making it an ideal material for a wide variety of buildings and infrastructure projects. Structural steel provides the framework for skyscrapers that define urban skylines, bridges that span rivers, and the robust frames of industrial buildings that house manufacturing capabilities. Moreover, advancements in fabrication techniques have improved the efficiency and safety of construction projects, leading to reduced overall costs and construction time.

Key Materials Used in Structural Steel Fabrication

The primary material used in structural steel fabrication is, naturally, steel. Various grades and types of steel, including carbon steel, alloy steel, and stainless steel, are selected based on the specific requirements of the project.

- Carbon Steel: Known for its strength and hardness, carbon steel is the most commonly used material in structural applications.

- Alloy Steel: Incorporating elements such as chromium, nickel, or molybdenum, alloy steel is used in projects requiring specific mechanical properties.

- Stainless Steel: Its resistance to corrosion makes stainless steel a preferred choice in architectural applications where aesthetics and longevity are critical considerations.

Steps in the Structural Steel Fabrication Process

Preparation and Design Phase

The initial phase of structural steel fabrication involves thorough planning and design. Architects and engineers collaborate to create detailed blueprints that specify dimensions, load bearings, and materials. Advanced software tools like Building Information Modeling (BIM) can facilitate this process, allowing for greater accuracy and efficiency. This stage is critical, as any errors in design can lead to significant issues during subsequent phases of fabrication and construction.

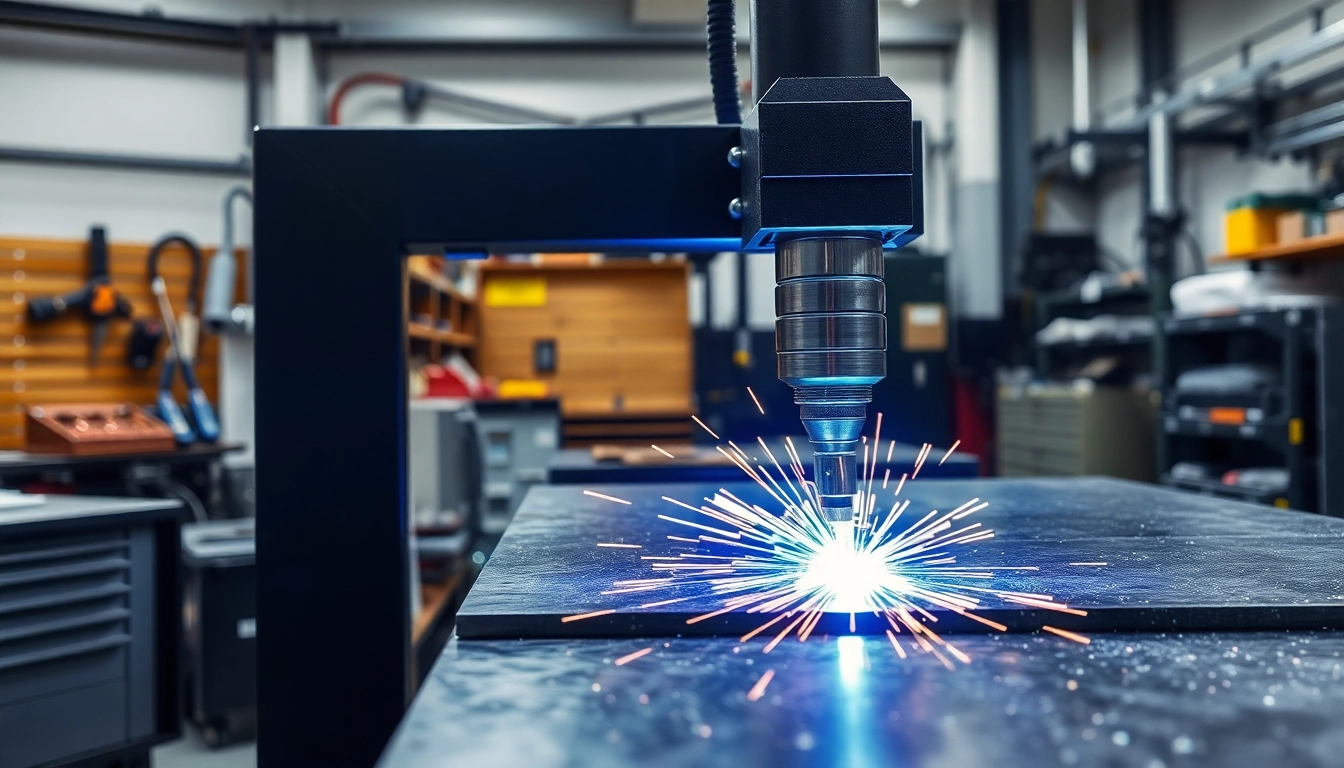

CNC Machining Techniques

Modern structural steel fabrication relies heavily on Computer Numerical Control (CNC) machining. This technology uses programmed software to guide machines in cutting, drilling, and shaping steel with high precision. CNC machines can perform complex tasks that would be challenging and time-consuming to execute manually. Moreover, automation reduces labor costs and enhances the safety of operations.

Welding and Assembly Methods

Once the steel components are machined, they undergo welding to assemble them into larger frames or structures. Various welding methods such as MIG, TIG, and spot welding may be employed depending on the thickness of the materials and the required bond strength. Additionally, after welding, quality checks such as X-ray or ultrasonic testing are essential to ensure the integrity of the welds before moving the fabricated components to the construction site.

Applications of Structural Steel Fabrication

Commercial and Industrial Structures

One of the most significant applications of structural steel fabrication is in the construction of commercial and industrial buildings. Steel’s ability to span large distances without support makes it ideal for warehouses, manufacturing plants, and office buildings, allowing for open floor plans and increased flexibility in interior layouts.

Residential Projects

In recent years, structural steel has gained popularity in residential construction. Custom homes often utilize steel framing for its strength and stability, especially in areas prone to extreme weather conditions. Steel framing also allows for innovative designs and is easier to modify during renovations compared to traditional wood framing.

Bridges and Infrastructure

Bridges are perhaps one of the most critical applications of structural steel fabrication. The material’s high strength-to-weight ratio enables the construction of expansive bridges that can carry substantial loads over long spans. Additionally, steel’s resilience to environmental factors makes it an ideal choice for durable infrastructural developments. The challenges associated with designing and fabricating bridges can be significant, but technological advancements in both computational design and manufacturing techniques have made these projects increasingly feasible.

Choosing a Structural Steel Fabrication Contractor

Evaluating Experience and Expertise

When selecting a contractor for structural steel fabrication, evaluating their experience and expertise is crucial. Reviewing their portfolio of completed projects can provide insight into their capabilities and style. Additionally, testimonials and case studies can serve as a useful gauge of their reliability and quality of work.

Understanding Cost Structures

Certain factors influence the cost of structural steel fabrication, including the complexity of the design, material costs, and labor rates. It is essential to have a clear understanding of these cost structures to avoid inaccuracies in budgeting. Engaging in open discussions and requesting detailed quotes from multiple contractors can assist in making informed decisions.

Importance of Certifications and Standards

Certifications and adherence to industry standards are vital aspects to consider when choosing a fabrication contractor. Look for companies that are certified in relevant standards, such as the American Institute of Steel Construction (AISC), which ensures that they meet specific quality and safety criteria. Compliance with these standards is crucial for maintaining safety and quality in construction projects.

Future Trends in Structural Steel Fabrication

Automation and Advanced Technology

The future of structural steel fabrication will be heavily influenced by advancements in automation and technology. Smart factories equipped with Internet of Things (IoT) devices can operate more efficiently, enabling real-time tracking of materials and production processes. Additionally, robotic welding and automated assembly lines are expected to reduce labor costs and improve consistency in product quality.

Sustainability Practices

Sustainability is becoming a crucial consideration in the structural steel fabrication industry. Utilizing recycled steel is already commonplace, but future trends indicate an ongoing commitment to reducing waste and emissions throughout the fabrication process. Strategies such as optimizing designs for material efficiency and employing greener manufacturing processes can contribute to the industry’s sustainability objectives.

Emerging Market Needs

As urbanization continues to rise globally, the demand for structural steel fabrication will grow. New market trends, such as the increasing need for resilient infrastructures due to climate change, will drive the development of innovative and robust design solutions. Fabricators must stay ahead of these trends, continuously adapting their capabilities to meet the evolving needs of the construction industry.